Manufacturing Excellence

Advanced quality inspection, automated assembly, 72-hour burn-in & full traceability for reliable gaming displays

Production Line

State-of-the-art production facilities with advanced equipment and technology

Surface Mount Technology

High-precision SMT assembly line with automated pick-and-place systems for consistent component placement.

LCD Panel Assembly

Specialized LCD panel assembly with precision alignment systems ensuring perfect display quality.

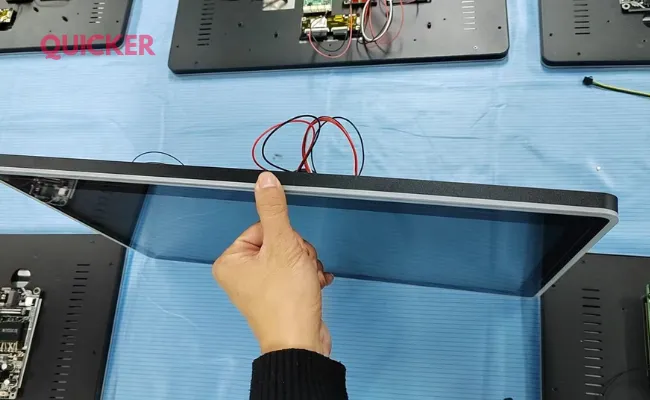

Touch Panel Integration

Advanced touch panel integration with optical bonding technology for seamless touch performance.

Final Assembly

Final assembly line with comprehensive testing and calibration for each gaming display unit.

Quality Control

Rigorous testing and quality assurance at every stage of production

Touch Accuracy Testing

Precision touch point testing to ensure accurate response across all 20 touch points with sub-millimeter accuracy.

Brightness Calibration

Professional brightness calibration ensuring consistent 1000+ nits output across all display units.

Environmental Testing

Comprehensive environmental testing including temperature, humidity, and vibration resistance validation.

Durability Testing

Anti-vandal and impact resistance testing to ensure displays can withstand demanding casino environments.

Packaging & Shipping

Professional packaging and secure shipping to ensure products arrive in perfect condition

Protective Packaging

Custom-designed protective packaging with foam inserts and anti-static materials for safe transportation.

Final Inspection

Comprehensive final inspection and documentation before packaging to ensure product quality.

Shipping Containers

Heavy-duty shipping containers with reinforced corners and moisture protection for international shipping.

Warehouse Storage

Climate-controlled warehouse storage with inventory management systems for efficient order fulfillment.

Manufacturing Statistics

Our commitment to quality and reliability in numbers

Certifications & Standards

Meeting international quality and safety standards

ISO 9001:2015

Quality Management System certification ensuring consistent quality processes and continuous improvement.

CE Marking

European Conformity marking ensuring products meet EU safety, health, and environmental requirements.

FCC Approved

Federal Communications Commission approval for electromagnetic compatibility and radio frequency compliance.

IP65 Rating

Ingress Protection rating ensuring dust-tight and water-resistant design for harsh environments.